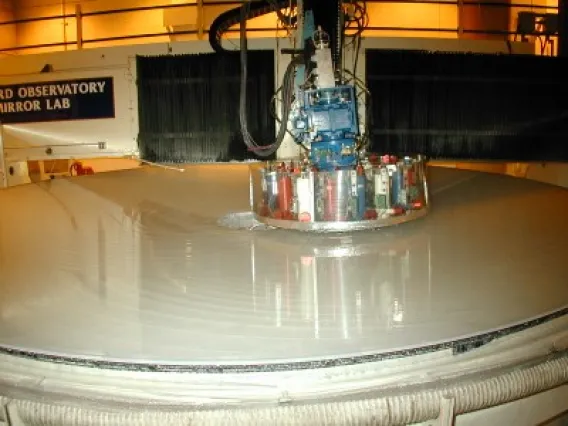

The back side of the Magellan II 6.5-m honeycomb mirror was generated flat during the summer of 1999. The photo at the left (by John Hill) shows a flat lap being used to polish the ground surface in early November of 98. The back side of the mirror blank is ground and polished to protect it from damage and to provide a good surface for glueing on the loadspreaders which support the mirror in its cell. The ventilation holes in the backplate of the mirror are plugged with rubber during this work in order to avoid filling the honeycomb structure with polishing slurry. The shipping box with the Magellan I 6.5-m mirror can be seen in the foreground.

By late-May 2000, the loose abrasive lapping process has smoothed the surface and improved the accuracy of the paraboloid to about 5 microns and so polishing begins. The shaped of the stressed lap is continuously adjusted under computer control to match the local curvature of the desired paraboloidal shape. By April 2001, The final polishing of the mirror was completed.